Coating for fruit and vegetables

VEGAN PROTEIN COATING AS SHELLAC AND PLASTIC ALTERNATIVE

Consumers are increasingly objecting to the use of plastic packaging for fruits and vegetables. And they are right. If anything is not environmentally friendly, it is plastic. Retailers defend the use of plastic because it also prevents food waste. Without a protective coating, the product has a shorter shelf life.

Many growers and retailers use shellac as an alternative to plastic. But shellac has its drawbacks.

There is an even better and more environmentally friendly alternative: a compostable, vegan, kosher, gluten-free solution! We believe and hope that this alternative will soon become the new norm in the vegetable and fruit market. This coating is the future.

THE CONSUMER IS BEING DECEIVED

We mentioned it a moment ago. Consumers are averse to all the plastic that is still widely used in fruit and vegetable packaging. Why are we banning plastic en masse for environmental reasons, but are our fruits and vegetables still often packaged in plastic?

This is why more and more products have been coated with shellac in recent years. It gives a nice shine, is better than plastic, and consumers are usually unaware that shellac has been used. As a result, few consumers know that their fruits and vegetables have been coated with shellac. Chances are that if consumers were aware, shellac would soon fall under the spell.

Shellac is a product derived from the resinous secretions of the lac bug, making it an animal-derived product. Not surprisingly, in 2024 the regulations in the UK will change for shellac. It may no longer be considered a “vegan” product.

SHELLAC COATING, WHY IS IT USED?

Shellac is used extensively in the food industry. This natural resinous sealant is non-toxic and FDA (Federal Drug Administration) approved for use on food. This gives the green light to use this natural product in the food industry.

But the production of shellac requires countless lac insects, which are found mainly on certain trees in Asia, especially in India and Thailand. The insects feed on the sap of the trees. The “lac resin” the insects produce is the excrement of the female insects to protect their eggs.

By all means, the insects are not killed, but collecting the excrement still brings along some lice and a lot of dirt, which has to be cleaned. A lot of water is used for this purpose.

Although shellac has been used for centuries, the way it is made today is not entirely environmentally friendly. But obviously much better than plastic.

SHELLAC FINISH SHINES AND PROTECTS

Just a step back. Why do we use shellac on fruits and vegetables at all?

First, it gives a nice shine. It makes the fruit look healthy and delicious.

It also protects food. Likewise, it helps retain moisture, prevents wilting and reduces the growth of mold and bacteria.

Because shellac is used as a barrier, it provides shelf life extension. It creates a controlled environment with reduced oxygen levels, which can slow down the spoilage process and preserve the freshness and nutritional value of the vegetables for a longer period.

Finally, the use of shellac (and plastics) reduces food waste. Products can stay on supermarket shelves longer. It also gives retailers the ability to import fruits and vegetables from more distant destinations.

WHY IS AN ALTERNATIVE TO SHELLAC COATINGS DESIRED FOR FRUIT AND VEGETABLE PACKAGING?

We have just highlighted some of the advantages and disadvantages of shellac.

The disadvantages at a glance:

- It is an animal (waste) product

- For religious or cultural reasons, shellac as an animal product is not acceptable due to dietary restrictions or beliefs

- In order to get the shellac clean, a lot of water will be used

- Regulations: Shellac is not seen as vegan anymore (2024 regulations in UK)

- It is also non-kosher and not gluten-free

- Limited biodegradability

THE SHELLAC ALTERNATIVE FOR FRUIT AND VEGETABLES: PROTEIN COATING

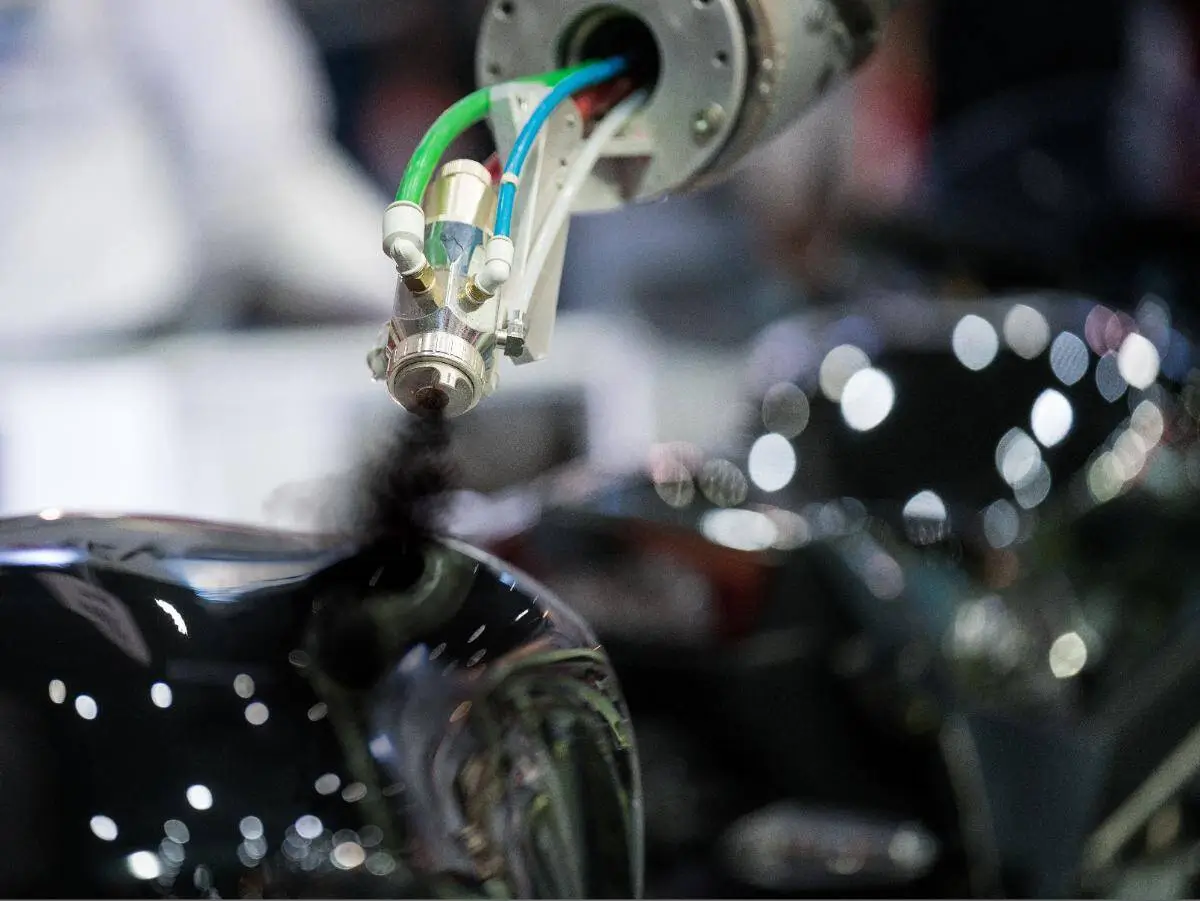

Vegetables and fruits that are currently packaged in plastics, or are shellac coated, can very easily be protein coated instead. Protein coating can be applied similarly to shellac and provides just as much protection for the fruits and vegetables.

This protein coating is made of corn. It is 100% bio-based, all natural!

- Non-GMO

- Vegan

- OU Kosher

- Gluten-free

- Lactose free

- Biodegradable, recyclable, bio-based

Compared to shellac, the production of protein is also less harmful to the environment. Corn is produced in many countries and is easy to grow. It takes less effort to gain corn compared to shellac.

In addition, protein coating, like shellac, has the advantage of adding a nice shine to the fresh product.

PROTEIN COATING IS SUITABLE FOR ALMOST ALL FRUITS AND VEGETABLES

Corn based protein coatings can be applied to nearly all types of fruits and vegetables. Consider application to apples, bananas, tangerines, citrus fruits, cucumbers, peppers, avocados, broccoli, potatoes, and many more fresh products. Only for leafy vegetables are protein coatings less suitable. Not because it can’t be done. Leafy vegetables can also be sprayed with protein coating very well, but consumers still find shiny lettuce and spinach leaves a bit odd.

STEP UP TO PROTEIN COATINGS, WE’LL HELP YOU

Plant-derived protein coating, is more easily broken down by natural processes. It is fully biodegradable. That’s why we believe protein coatings are the future for protecting and extending the shelf life of fruits and vegetables, and why we at adhesives+coatings are eager to help growers and retailers make the switch to this highly environmentally friendly product.

Can we help you make the switch? Interested in learning more about protein coating? Then please contact us.

What solution are you looking for?

We are specialized in the vegan protein coating as plastic and shellac alternative for fruit and vegetables. Need the best products or advice? Then please leave your details and we will get in touch.