Powder coating for appliances

Powder coating for more durability with an aesthetic touch

As we rely more and more on appliances in our lives, it only makes sense to treat them with care. However, accidental neglect can still happen, and for that we have a great preventative measure to get the most out of your appliance's life: powder coating. It protects equipment from a variety of factors that can affect product life, such as high temperatures, wear, or chemicals in cleaning products. Plus, powder coating offers a variety of colors to choose from for each appliance. The powder coating thus not only provides protection, but at the same time can be used as a powder paint. In the following paragraphs, we will give you the reasons why other people and companies have chosen to use powder coating.

Advantages of powder coating in the appliance industry

Before we give reasons, it might be better to look at the numbers. At least 75% of the industrial coatings in the appliance industry are powder coatings. This shows that powder coating appliances is not a niche industry. Powder coating appliances are proving to be beneficial to the coaters themselves, the users of the appliances as well as the general environment as will be shown below:

- Safe for people and the environment: Powder coating is a safe and environmentally friendly option for people and companies looking for a high quality coating option because it does not emit VOCs. In addition, there is almost no waste as overspray is not an issue as 95% of the overspray can be recovered and recycled for reuse.

- Efficient: Powder coating is the way to go when you want a cost-effective option that doesn't take long - it only takes minutes to cure! Plus, applying the single coat is super easy when done with an automated process.

- Offers resistance: As mentioned above, powder coating provides an extra layer of protection against hot temperatures or chemicals in cleaning supplies.

- Protects durability: The powder coating resists wear and chipping from other objects while protecting against accidental scratches or bumps.

- Finishing touch: Finally, it can add a glossy finish to the product with a wide variety of colors or textures.

Powder coating appliances: the process behind it

The process itself is quite simple and consists of two stages:

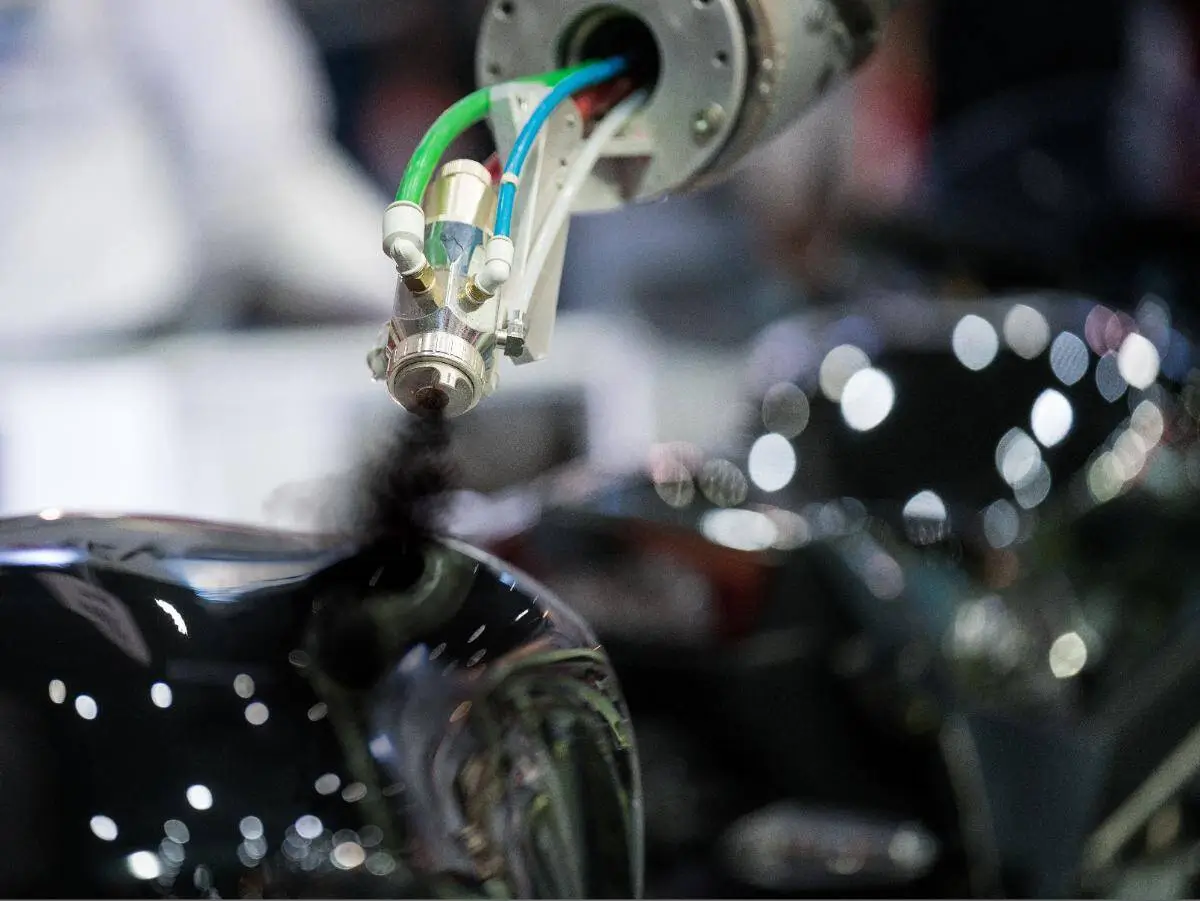

- A dry powder is applied to the top layer of the device by electrostatic charge. This is done using a specially designed spray gun that releases this electrostatic charge as it sprays.

- The part itself (in this case, part of the appliance) is then baked, melting the powder coating into a solid layer. Baking is what gives the finishing shiny touch.

Actually, there are two variations to this simple process, as there are two different types of coating powders, thermoplastic and thermoset. What adds a difference between the two is the curing method that happens during the baking stage; where thermoset coatings would bond through a network of cross-linked chain polymers, making it a durable and resistant coating, thermoplastic coating on the other hand does not form cross-links and neither is its coating as heat resistant as thermoset. Therefore, thermoset coatings are used for powder coating of equipment. Epoxy, polyester, epoxy-polyester and polyurethane are all used as the base resin for these powder coatings. The most common resin is polyester or a hybrid of epoxy and polyester. These can be used as a basecoat, topcoat, primer or even a coat that adds special effects.

Innovations in powder coatings

adhesives+coatings is committed to contributing to the use of more environmentally friendly coatings and adhesives. There are many wonderful developments in the field of powder coatings. Some examples:

- New powder coatings are being developed that can achieve the same strength with a thinner layer.

- Powder coatings that can be applied to multiple types of materials, not just metals.

- Powder coatings that have a shorter cure time.

- New automated powder coating application methods are being developed that give less waste

- The ingredients in powder coatings are also becoming more durable.

Looking for an industrial powder coating that is more eco-friendly?

adhesives+coatings can help you find the right innovative coating for your appliance.

What solution are you looking for?

We are specialized in the powder coating for appliances. Need the best products or advice? Then please leave your details and we will get in touch.