Transport & Vehicles

Transportation and automotive adhesives

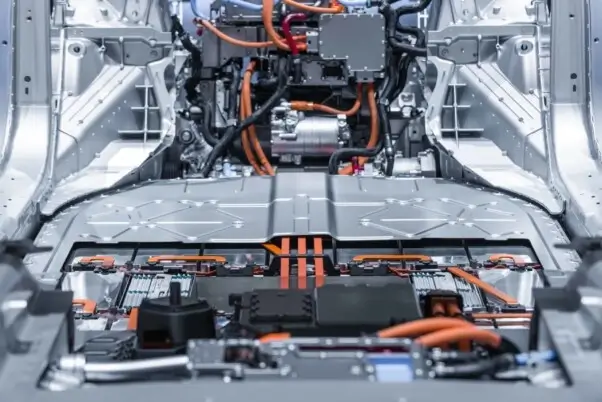

The transport and vehicles sector is continuously challenged by the desire for lighter weight vehicles with increased durability as well as faster and greener production processes. Transport adhesives and sealants contribute a great deal to realizing these lighter, stronger, faster and greener transport vehicles.

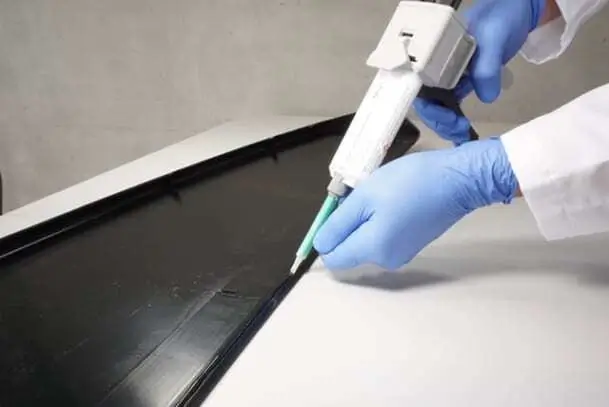

Like many industries, also the transport and vehicles sector is shifting away from welded bonds and mechanical fasteners, and replacing them with adhesives and sealants. Contributing to safety and comfort, adhesives and sealants are growing their popularity in the transport industry. Seals and bonds are formed both inside and outside vehicles such as trains, buses, trucks and trains.

Transportation adhesive and sealant systems

Transport adhesives come in many formulations and are suitable for a wide range of applications. Currently the most interesting adhesives for transport vehicles include methyl methacrylate (MMA) and modified silane polymer (SMP). On the other hand, the most interesting transport sealants rely on MS polymer technology which is a type of SMP. Also the more traditional adhesive and sealant systems, such as polyurethane, silicone and epoxy, serve the transport and vehicles sector providing long lasting bonds and seals.

Benefits for the process and products

Adhesives and sealants for transport are suitable for many applications from window direct glazing and interior trim to panel bonding and body structures. The increased use of chemical seals and bonds is easily explained by the numerous benefits they provide to both the process and finished products.

- Faster production

- Lower material costs

- Lower labor costs

- Supporting automated assembly lines

- Lighter weight vehicles

- Reduced corrosion risk

- Lower fuel consumption

- Improved safety and crash performance

Assistance and service

Our experts are dedicated to assisting you in finding the most suitable transport adhesives and sealants for your vehicles and production processes. Share your transport adhesive or sealant needs with us and let us find the best solution for the job.