Food-safe plastic adhesive for filter elements

Adhesive for plastic substrates in filter elements

In most industries liquids and gasses are filtered for various purposes and reasons. A wide variety of filtration element types have been developed, all with slightly different properties. These filters or cartridges have become increasingly high-tech over the last decades. Unsurprisingly, more complex structures also require more specialized adhesives and sealants.

Part of the problem is the fact that these products must incorporate a growing number of properties to perform their tasks. Let’s look at a few typical requirements.

The adhesive or sealant must be viscose enough for controlled application, but also fluid enough to maintain a proper and predictable flow during application. Picking an adhesive with the correct thixotropy can greatly prevent application issues during manufacturing.

When used as a bonding agent, that bond must be strong enough to serve its purpose, while also being able to withstand rigorous manual or chemical cleaning methods. And, when the unit is discarded, the unit or parts of it must be recyclable in a manageable way, or biodegradable.

Another vital quality is food safety. Many of these filtration systems are used in industries that process food or beverages, or are part of water purification systems. It goes without saying that every part that comes into contact with food or beverages must be absolutely safe.

Your company requires a high-tech, strong bonding adhesive sealant that is safe for use in the food & beverage industry? Contact us for more information.

Food-safe adhesive for filter elements

Adhesives and sealants made for use in the food and beverage industry preferably don’t contain plasticizers. Using a safe, natural ingredient like castor oil as a base makes a lot of sense.

Castor oil is a natural vegetable oil that is used in a wide range of beauty products and for a number of medical applications. Aside from its boasted useful antimicrobial and antiinflammatory properties, it can also serve as a perfect basis for a number of products, suitable for use in the food & beverages industry, as well as in other applications.

With rules and regulations becoming stricter every year, it can be increasingly hard to find your way in the growing market of adhesives. More so, when these adhesives have to be environmentally friendly and comply to health & safety regulations. This is exacerbated by the fact that every application has its own specific requirements.

Polyurethane adhesive for plastic substrates in filtration cartridges

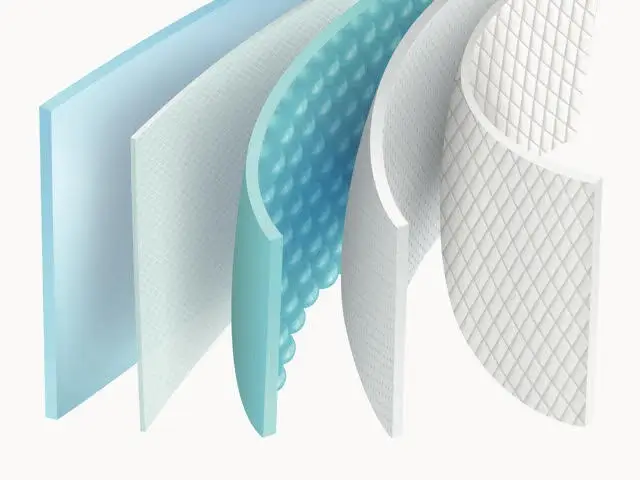

We often see there is a wish for adhesives that also act as sealants. A typical usage is the manufacturing or assembly of spirally wound filtration membranes or other replacement filter elements, i.e., for filtering of water, dairy products, and beverages.

A two-component polyurethane sealant for plastic substrate components would be a sensible choice. The combination of high strength bonding and permanent elasticity allows for a wide range of applications with only one product. This is a great way to simultaneously streamline your production method and cut costs.

Not just any polyurethane sealant will do. When it comes to filter elements for the food & beverage industry, the adhesives and sealants must be fully compliant with the NSF/ANSI standard 61. Using an unsuitable alternative could lead to undesirable or even unsafe results.

Application suitability, thixotropy and regulations aside, there may be other things to consider as well. Mixing ratios and methods spring to mind, as well as curing times and conditions.

In relation to shipping and compatibility with your production process, you might want to know if it is available in the package format of your preference, like IBC totes or drums.

Looking for an adhesive with specific properties?

adhesives+coatings is specialized in finding the best eco-friendly adhesives and sealants for existing and developing niches. Contact us and we will guide you towards the perfect solution for your requirements.

What solution are you looking for?

We are specialized in the packaging and paper. Need the best products or advice? Then please leave your details and we will get in touch.